The optimal trike?

When we first started looking at different trikes on the market, we quickly realized that they all lacked many things. We asked ourselves questions. Such as:

-

Why are they so heavy?

-

Why are they so wide that they can’t easily pass through a doorway or travel on narrow bike paths?

-

Why isn’t the knowledge from racing cycling and recumbents lowracer being used?

-

Why not utilized carbon fiber at its potential?

-

Why they were often not optimized aerodynamically?

-

Why weren’t the trikes constructed in a practical and smart way?

And so the idea of creating a super-light trike, with practical features was born. It should be narrow enough to be aerodynamic and to get through a doorway. We wanted to make man and machine into a dynamic unit.

It wasn’t before long we started to make great achievements when we used light and advanced materials. This is what has made CARBONTRIKES the lightest and fastest serial production trike ever made. This includes extreme racing trikes. The difference is that our construction, in addition to its extremely low weight, also allows daily use and touring.

Advanced manufacturing

The production of CARBONTRIKES trikes, wheels and accessories are made by hand and are carried out in accordance with the latest findings and best manufacturing processes available. It is the same methods and materials used in modern supercars, aircraft and the aerospace industry.

Our innovative production process begins with computer-controlled cutting of high quality carbon fiber fabric that is oriented and placed in specially made moulds. The parts cure under high pressure and heat to achieve maximum quality and strength. Exact temperature, increase in temperature, peak temperature and curing times are carefully calculated and tested to provide maximum strength to the carbon fiber laminates. We use prepreg or dry carbon fiber depending on the purpose.

To laminate the dry carbon fiber, we use only high-end low viscosity epoxy specially formulated for carbon fiber. We work closely with some of the leading manufacturers of carbon fiber products in the world. CARBONTRIKES are manufactured with carbon fiber that comes from the world's leading manufacturers. We have close contact with Scandinavia's most successful developer and producer of epoxy laminating system (the material that binds the carbon fiber fabric).

To protect the trike uses CARBONTRIKES 2-component special paint suitable for carbon fibers. That is cured in the heat. For maximum control we paint the frame by hand. The process is the best from an environmental standpoint. The method may give small optical defects compare to traditional spray painting. But it provides an extremely low weight. Despite the large surfaces of the trike, the paint on the frame weight only 22 grams / 0,77 oz.

Benefits of Carbon Fiber

There are many advantages of a carbon fiber construction compared to trikes built in metal. This is particularly true especially if the entire frame and all vital parts is also built of carbon fiber. A trike built in carbon has significantly higher stiffness to weight ratio compared to a trike built in aluminum or steel. Carbon does not suffer from exhaustion - something that is common for aluminum. Weight savings are often 50 percent or more compared to aluminum.

When designing a trike in carbon fiber composites, the design of the trike must be made according to how carbon fiber works. A trike made of carbon fiber cannot be built after the metal's properties (which is a mistake we've seen a lot of on the trike market). To construct a trike out of composite is technically much more advanced, but the possibility to achieve a flawless product increases.

Fiber Composite is an anisotropic material, unlike metal which is an isotropic material. This mean that metals has exactly the same properties in all directions, while using fiber composite allows controlling the properties by orienting the fibers. So the stiffness, damping, weight and design can be controlled entirely by the structure's needs and not vice versa.

Damping capacity of composite materials is well known, combined with the ability to control the stiffness in different directions depending on how the carbon fiber cloth is laid. The carbon fiber’s damping ability will remove vibrations from the road and eliminates the need for mounting heavy and expensive mechanical suspension system.

Monocoque

All CARBONTRIKES composite parts are built according to the monocoque principle. Which means that all carbon fiber parts are manufactured in one piece, at the same time - without any weakening joints or heavy metal parts. This makes it light, stiff, strong and safe.

Monocoque construction is the most efficient and optimized way to design a trike made of carbon fiber. The design is superior to those currently on the market, which is based on pre-fabricated carbon fiber tubes which are glued together with metal parts. To construct this way means that almost all the advantages of using carbon fiber are lost.

Product development

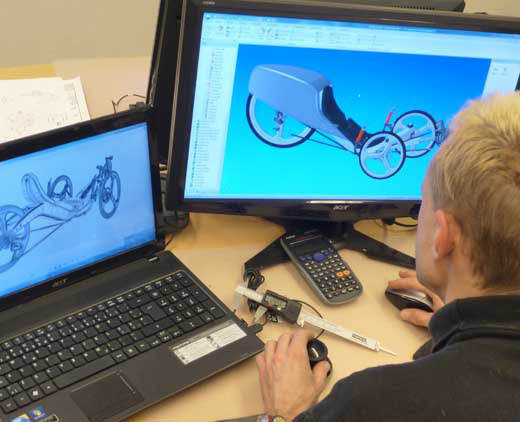

All product development and composite manufacturing is done at CARBONTRIKES in Sweden, to achieve full control and ensure consistent high quality. Other parts and accessories are carefully selected and tested. Product development takes shape based on sketches. After that the ideas are then implemented in a CAD-system using the latest technology. From the CAD-models we create prototypes that are manufactured under rigid control and with careful craftsmanship.

Our goal is to create light, fast and user friendly products that are market leaders. To succeed, we have a large network of top specialists and researchers to assist us with their knowledge. CARBONTRIKES also has frequent exchanges with some of the leading manufacturers of carbon products in the world. Although we are a small company, we have the unique expertise required to create a world-leading carbon fiber trike.

Safety

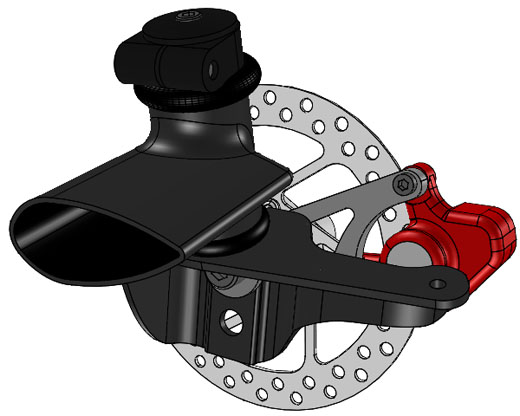

CARBONTRIKES motto is lightweight. Of course, without compromising the riders safety. Therefore, trike, wheels and accessories are thoroughly tested. A natural step in safety is to use a hydraulic brake systems. Dual hydraulic and ventilated disc brakes on front wheels reduces the braking distance significantly compared to a traditional racing bike or two-wheel recumbent. Compared with other trikes CARBONTRIKES low weight further contributes to minimize the braking distance. Hydraulic brakes also provide grip regardless of weather. Rain, snow and cold weather is no problem.

Even if the road surface is slippery, our trikes low center of gravity is always a safe and secure handling. CARBONTRIKES goal is to deliver the speed and the low weight of a lowracer. But safety and ease of use of a trike.

Design

We think that form should follow function. But that doesn’t mean that the design shouldn’t be pleasing to the senses. Smart and practical solutions are something we strives at CARBONTRIKES.

We are proud of the design in our products, but we also have a close collaboration with external industrial designers. Carbon structures provides significant design opportunities to give minimal weight, high stiffness, good vibration damping and to make the trike attractive and aerodynamic.

CARBONTRIKES has an adjustable size to fit different riders. The seat size and boom length is variable. As a result of this the trike will fit the rider perfectly and the second hand value will be kept at a high level.

Performance

To optimize and evaluate the aerodynamics and efficiency of our products, we use the SRM power measurement systems. We have hired the heaviest and strongest Swedish elite cyclist* we could find for the analysis of extreme load, power and speed. In our tests, we can see that the rigid frame allows the rider to push the pedals to generate maximum reward and momentum with each revolution. No matter how much technology we use, we will never stop evaluating our Trikes in a human way - how it feels and is perceived - CARBONTRIKES is always a machine built for pleasure!

*194 cm/101 Kg/+1700 watt (Over two horse power!)

In the integrated and adjustable seat is a practical space for example: spare tubes, tools, pump, valuables, Powerbar, rain jacket, and a 2 liter water bag.

CARBONTRIKES has developed a completely new type of boom. Its elliptical shape preventing rotation. The design also makes it both lighter and stiffer than round.

CARBONTRIKES frame built in one piece so called monocoque - to provide maximum strength and minimum weight.

It takes many hours of CAD software before we develop a new product.

The powerful hydraulic brakes are fitted as standard.